Industrial Flexible High Pressure Steel Wire Hydraulic Rubber Fuel Oil Hose with Fitting Factory

KEY PERFORMANCE: EN/DIN and new SAE rated working pressures Appearance: Wrap( I.D less than 25.4mm smooth cover) Brandin

Basic Info

| Model NO. | sae 100 r2 |

| Material | Nr, SBR, NBR, Cr, EPDM etc Rubber |

| Capability | Transport for Petroleum, Oil, Water, Gas etc |

| Color | Black, Red, Blue, Yellow, Green, Gray |

| Size | 1/4, 5/16, 3/8, 1/2, 5/8, 3/4, 1, 1/1/4, 1/1/2, 2 |

| Working Pressure | 50-500 Bar |

| Type | R1. R2. R3. R4. R5. R6. R7. R8. R9. R14. R16. R17 |

| Standard | GB / DIN / SAE |

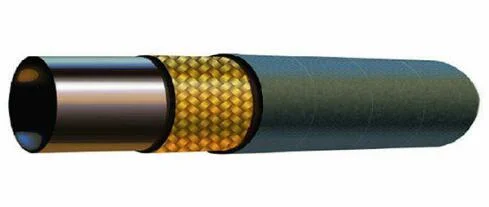

| Tube | High Temperature and Oil Resistant Synthetic Rubbe |

| Reinforcement | High Tensile Steel Wire |

| Cover | Abrasion, High Temperature, Oil and Weather Resist |

| Application | Hydraulic Fluids, Industrial, Agriculture |

| Connector | NPT, Bsp Carbon / Stainless Steel Fitting |

| Transport Package | PP Woven Bag or as Customized |

| Specification | 5-51mm, 3/16′′ - 2′′ |

| Trademark | OEM |

| Origin | China |

| HS Code | 4009210000 |

| Production Capacity | 700000 Meters One Month |

Product Description

KEY PERFORMANCE: EN/DIN and new SAE rated working pressures

Appearance: Wrap( I.D less than 25.4mm smooth cover)

Branding: Printing and indelible branding with embossed technology

Colour: Black, red, blue, yellow, green, gray

Continuous service temperature range: -40°f / +212°f; -40°c / +100°c

Max operating temperature: 250°f 121°c

Insert: shf-type

Tube: oil resistant synthetic rubber

Reinforcement: one high tensile steel braid

Cover: environment resistant synthetic rubber

Applicable specs: EN 853 1SN - SAE 100 R1AT - ISO 1436-1 1SN/R1AT

APPLICATIONS & FLUIDS

Hydraulics: Low-medium pressure lines, return lines

Mineral oils, vegetable and rape seed oils, glycol and polyglycol based oils, synthetic ester based oils, oils in aqueous emulsion, water.

SAE 100 R1 AT HT/ DIN EN 853 1SN HT

| DN | Hose I.D | Wire O.D | Hose O.D | Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | Length | |||

| inch | mm | mm | mm | MPa | psi | MPa | psi | mm | kg/m | meters | |

| 5 | 3/16 | 4.8 | 9.5 | 11.8 | 25.0 | 3630 | 100.0 | 14280 | 89 | 0.19 | 50/100 |

| 6 | 1/4 | 6.4 | 11.1 | 13.4 | 22.5 | 3270 | 90.0 | 12840 | 102 | 0.21 | 50/100 |

| 8 | 5/16 | 7.9 | 12.7 | 15.0 | 21.5 | 3120 | 85.0 | 12280 | 114 | 0.24 | 50/100 |

| 10 | 3/8 | 9.5 | 15.1 | 17.4 | 18.0 | 2615 | 72.0 | 10280 | 127 | 0.33 | 50/100 |

| 13 | 1/2 | 12.7 | 18.3 | 20.6 | 16.0 | 2320 | 64.0 | 9180 | 178 | 0.41 | 50/100 |

| 16 | 5/8 | 15.9 | 21.4 | 23.7 | 13.0 | 1890 | 52.0 | 7420 | 203 | 0.45 | 50/100 |

| 19 | 3/4 | 19.0 | 25.4 | 27.7 | 10.5 | 1530 | 42.0 | 6000 | 241 | 0.58 | 50/100 |

| 25 | 1 | 25.4 | 33.3 | 35.6 | 8.8 | 1280 | 35.0 | 5020 | 305 | 0.88 | 50 |

| 32 | 1 1/4 | 31.8 | 40.5 | 43.5 | 6.3 | 920 | 25.0 | 3600 | 419 | 1.23 | 20 to 40 |

| 38 | 1 1/2 | 38.1 | 46.8 | 50.6 | 5.0 | 730 | 20.0 | 2860 | 508 | 1.51 | 20 to 40 |

| 51 | 2 | 50.8 | 60.2 | 64.0 | 4.0 | 580 | 16.0 | 2280 | 635 | 1.97 | 20 to 40 |

SAE 100 R2 AT / DIN EN 853 2SN HT

| DN | Hose I.D | Wire O.D | Hose O.D | Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | Length | |||

| inch | mm | mm | mm | MPa | psi | MPa | psi | mm | kg/m | meters | |

| 5 | 3/16 | 4.8 | 11.1 | 13.4 | 41.4 | 6000 | 16 | 23720 | 89 | 0.32 | 50/100 |

| 6 | 1/4 | 6.4 | 12.7 | 15.0 | 40.0 | 5800 | 160 | 22840 | 102 | 0.36 | 50/100 |

| 8 | 5/16 | 7.9 | 14.3 | 16.6 | 36.0 | 5250 | 140 | 20000 | 114 | 0.45 | 50/100 |

| 10 | 3/8 | 9.5 | 16.7 | 19.0 | 33.1 | 4800 | 132 | 18840 | 127 | 0.54 | 50/100 |

| 13 | 1/2 | 12.7 | 19.8 | 22.2 | 27.6 | 4000 | 110 | 15720 | 178 | 0.68 | 50/100 |

| 16 | 5/8 | 15.9 | 23 | 25.4 | 25.0 | 3630 | 100 | 14280 | 203 | 0.8 | 50/100 |

| 19 | 3/4 | 19.0 | 27 | 29.3 | 21.5 | 3120 | 85 | 12280 | 241 | 0.94 | 50/100 |

| 25 | 1 | 25.4 | 34.9 | 38.0 | 16.5 | 2400 | 65 | 9420 | 305 | 1.35 | 50 |

| 32 | 1 1/4 | 31.8 | 44.5 | 48.3 | 12.5 | 1820 | 50 | 7140 | 419 | 2.15 | 20 to 40 |

| 38 | 1 1/2 | 38.1 | 50.8 | 54.6 | 9.0 | 1310 | 36 | 5140 | 508 | 2.65 | 20 to 40 |

| 51 | 2 | 50.8 | 63.5 | 67.3 | 8.0 | 1160 | 32 | 4560 | 635 | 3.42 | 20 to 40 |

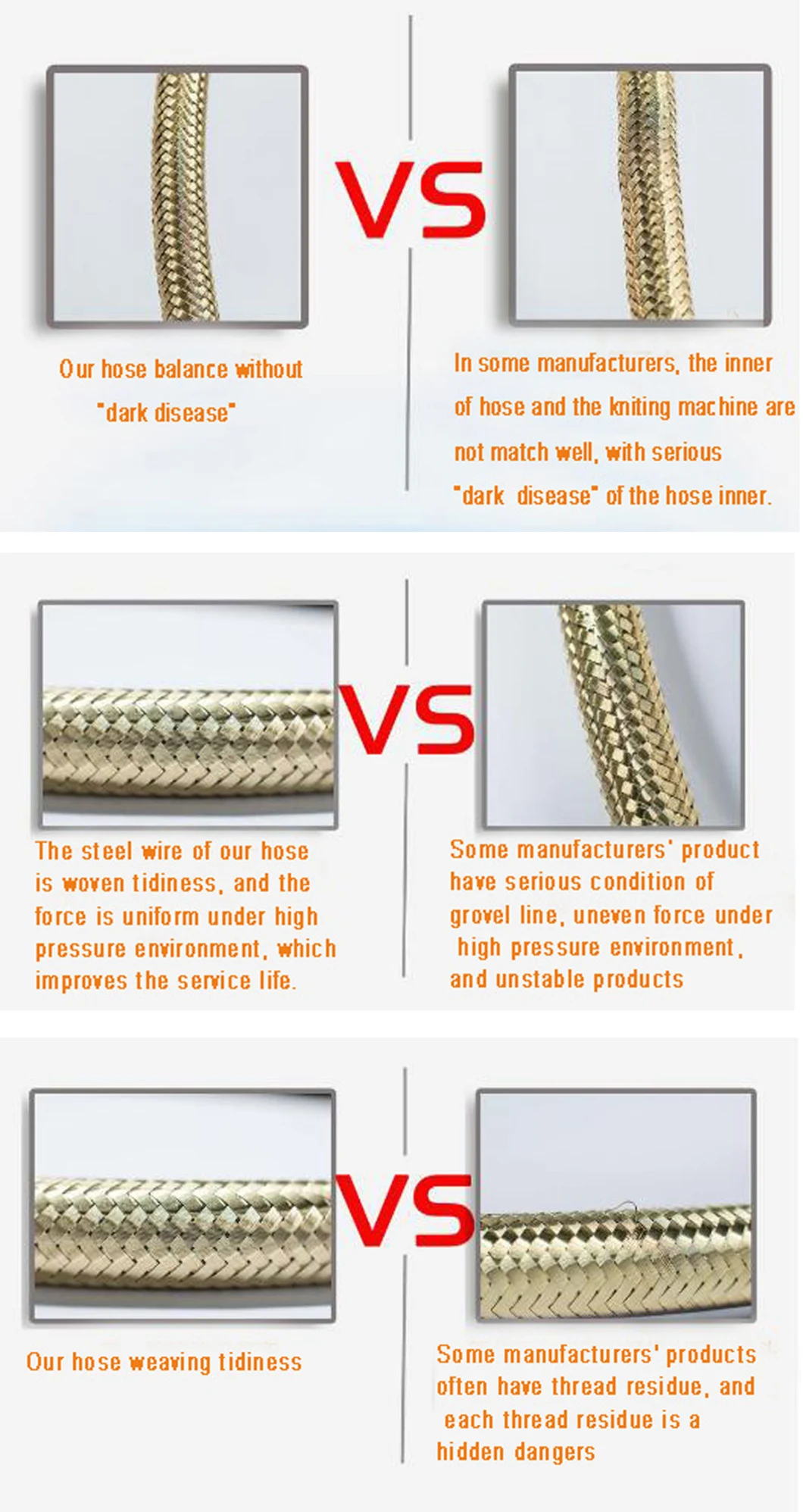

Quality VS:

Our Products Range:

1. Hydraulic Hose

Steel wire braided hose, Steel wire spiral hose, Texible braided hose

2. Industrial Hose:

Smooth(Wrapped) Air/Water/Oil/Gas/Lpg hose, Welding hose, Oxygen hose, Acetylene hose,

Lpg hose/Propane hose, Twin hose, Oil/Water suction and discharge hose, Steam hose, Sandblast hose,

Large diameter hose etc.

3. Automotive Hose

Air brake / condition hose, Power steering hose, Fuel oil hose,

4. PVC Hose

5. Hose Fitting / Coupling / Ferrule

6. Hose Machine

Optional accessories for hose fitting adaption:

Application Field:

For engineering machinery, port machinery, aerospace, car manufacture, machine tool manufacturing, wind power manufacturing, shipbuilding industry, engine, textile machinery, petrochemical, agricultural machinery, mining machine, construction machinery, special vehicle, matall urgical machinery, injuction food machinery, printing machine, railway, hydraulic system, water conservancy construction

Workshop Show:

≡ FAQ

Q: Do you produce smooth or cloth wrapped cover?

A: Yes, we can produce both cover, which depends on customer's request.

Q: Can you produce product with my own brand?

A: Yes, OEM or ODM is warmly welcome by our company. Hope we both parties will benefit a lot through the cooperation.

Q:Could we get free samples?

A: Yes. We can provide the free sample for you

Q: Does your product have different color hose?

A: Yes, we currently provide black, grey, red, blue and yellow.

Q:Could you crimp hose?

A: Yes, we can crimp hose assembly for our customers

Q: How long does my order take to be delivered?

A: It usually takes 5 to 30 days, which generally depends on the quantity of your order and our storage.

If you are interested in our products or if you have special requirements, Welcome to Contact Us With Any Enquiries!

Send to us