Top Quality Universal Auto Custom EPDM Rubber Radiator Hoses

Basic Info

| Model NO. | Epdm Rubber Hose |

| Application | Auto or Other Engines |

| Hardness | 35~80 Shore a |

| Shape | Custom Shape |

| Transport Package | Customized Packaging |

| Specification | customized size |

| Trademark | OEM |

| Origin | China |

| HS Code | 3917310000 |

| Production Capacity | 5ton/Month |

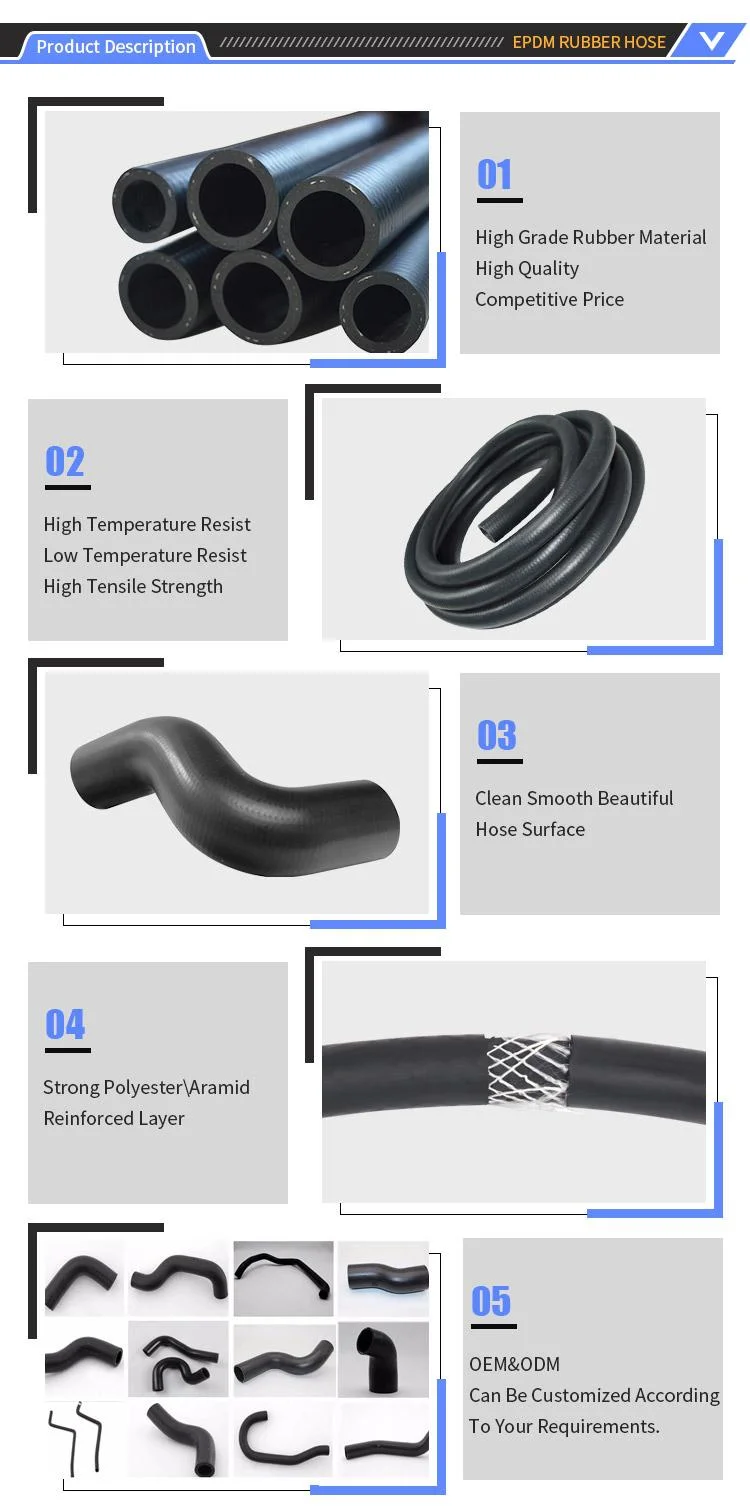

Product Description

Products Description

Product Name | EPDM rubber hose |

Material | EPDM+polyester fiber braided |

Production Process | Inner hose: EPDM, Reinforcement: PET, Cover: EPDM |

Product Surface | smooth surface with pure rubber |

Product Feature | EPDM material have superior performance, tensile strength, anti-aging, |

Work Pressure | 1.5Mpa=15kg=15bar=145Psi or customized |

Blasting Pressure | 3.0Mpa=30kg=30bar=290Psi or customized |

MOQ | 1000PCS |

Application | automotive, mechanical water tanks, engines, radiators, heaters etc |

only use only the finest quality EPDM rubber for the most demanding automotive applications.This ensures Hoses perform better and look great without fading or perishing over time.

2. Premium Quality Reinforcing Fabrics use the finest Aramid/Polyester fiber, specially designed for automotive hose manufacturing. Fabrics are specially orientated to give required stiffness to resist dilation-associated problems such as loss of boost.Only with quality fabric will the hose have the strength to deliver reliable performance.

3. Complex Constructions Not all the hoses are the same - each Hose has a specific combination of EPDM compounds & selected fabrics to deliver the required performance, reliability strength and flexibility required, as well as complex bespoke shapes to suit every need.4. Can be CustomizedAny shape, size, size can be customized according to customer requirements

Tips:

The price and package size of this product are for reference, please contact the salespersonCustomers Comments

Our products are highly praised, customers give us five-star reviews without exception, and have reached long-term cooperative relationships with many customers

Product ProcessCompany Profile

Silicone tubes have great applications in life. The most common applications include medical silicone tubes, baby bottle nipple silicone tubes, corrosion-resistant silicone tubes, water dispenser silicone tubes, etc. It can be seen that silicone tubes are indispensable in life. , So, having said so many applications of silicone tube, do you know what are the production process of silicone tube? Do you know the specific process knowledge? Let me know about it with me~

Extrusion production process of silicone hose:

1. Rubber mixing: The raw materials of the rubber compound are mixed in the twin-cylinder rubber mixing machine with double 24 or platinum vulcanizing agent or silica gel masterbatch, and then pressed into a layer of silicone extrusion material with uniform thickness.

2. Extrusion molding: install the mold on the head of the silicone extruder. Divide the refined rubber into shapes of the same size and length so that it is convenient to feed the material from the inlet of the extruder. Then feed the material through a silicone extruder, extrude the molded but very soft silicone hose, put the silicone hose into an 8-meter-long drying tunnel, and vulcanize at high temperature. The silicone hose that comes out through the drying tunnel can be a semi-finished product, and then wrap it.

3. High-temperature vulcanization: Put the wound silicone hose in the oven, normal silicone 180 degrees, gas-phase silicone hose 200 degrees, high temperature for 2 hours, perform secondary vulcanization to remove the odor on the silicone hose, prevent blooming and change Yellow.

4. Perform follow-up processing: the rest is to perform follow-up processing such as cutting or bonding according to the length required by the customer. Then package and ship to customers as required.

The products of our factory are mainly used in automobiles, trucks, machines, and various important mechanical parts, as well as various silicone products

Our factory is over 2000 square meters, has 700 experienced workers and 7 kinds of production lines, and has trade relations with more than 200 countries. Repurchase rate as high as 99%Our Services1. can produce Silicone and EPDM Hoses according to OEM number, Samples or Drawings.2. Small Quantity is acceptable.3. Samples can be provided for quality confirmation.4. Certificates can be provided if you need.5. Printing according to your request6. Custom-built Hoses are highly welcome.FAQ1.Question: There are many unqualified hookah in the market, how can you make sure your quality control?Answer: We have past ISO9001 certificate, more than 100 quality inspection personnel, in strict accordance with the international standard production.2.Question: How about your production capacity,and how can you make sure my goods would be delivery timely?Answer: Supply Ability: 10000 Pieces/month, late delivery refund 5000 per day.3.Question: How about your design ability? Do you offer OEM service?Answer: we have our own design department, and have offer design service for thousands of cooperative partner. OEM accept and offer confidentiality agreement "business secret contract" for your design safe.4.Question: Can I place one small order for first time to test the quality?Answer: Small order are also welcomed, and we offer new customers 3% discount for first order and offer free sample.5.Question: Can I visit your factory?Answer: Your are wecomed to visit our factory,and we offer free hotel and free car.

About Us

Hebei Conqi Vehicle Fittings was established in 2007 and is a professional rubber hose manufacturer.The products include rubber hose for water,air and oil etc,and other auto parts etc.

Our factory covers an area of 5 hectares and the workshop area is 45,000 square meters. We have a complete rubber mixing process, cold feed extrusion process, microwave vulcanization process and high-speed braiding process and other production lines.